The Importance of booster compressor oil and Gas

What is meant by booster compressor oil and gas?

The terms booster compressor oil and gas are employed when discussing the specific lubricants and gases used in booster compressors to guarantee their appropriate operation and performance. Gas and oil for booster compressors are crucial in keeping them effective, dependable, and long-lasting. While the gas is in charge of the compression, the oil offers lubricating and heat dissipation qualities. Businesses may ensure efficient operations, lower their energy consumption, and increase the lifespan of their booster compressor systems by utilizing suitable and high-quality oil and gas. The performance of booster compressors is further improved by routine maintenance, which includes oil analysis and monitoring. This allows for proactive maintenance and maximizes operating efficiency. Here is a quick description of each:

- Booster Compressor Oil:

Designed specifically to fulfil the specific needs of booster compressors, booster compressor oil is a specialized lubricant. These lubricants are intended to minimize wear between the compressor’s moving parts, offer good lubricating qualities, and reduce friction. They also have good thermal stability, which helps them endure the high temperatures produced during compression. Additionally, booster compressor oils frequently include chemicals that protect against oxidation, corrosion, foam formation, and other possible problems that could occur in the compressor system.

- Booster Compressor Gas:

Booster compressor gas is the particular gas that booster compressors utilize to compress air. The application and the compressed gases in the system influence the gas choice. Air, nitrogen, hydrogen, natural gas, and numerous industrial gases are frequently utilised in booster compressors. The booster compressor gas must have the appropriate purity levels and moisture content to ensure effective and dependable operation. The compressor’s performance can be impacted by contaminants or too much moisture in the gas, creating corrosion and operational problems.

Improving Efficiency and Performance: The Importance of Booster Compressor Oil and Gas

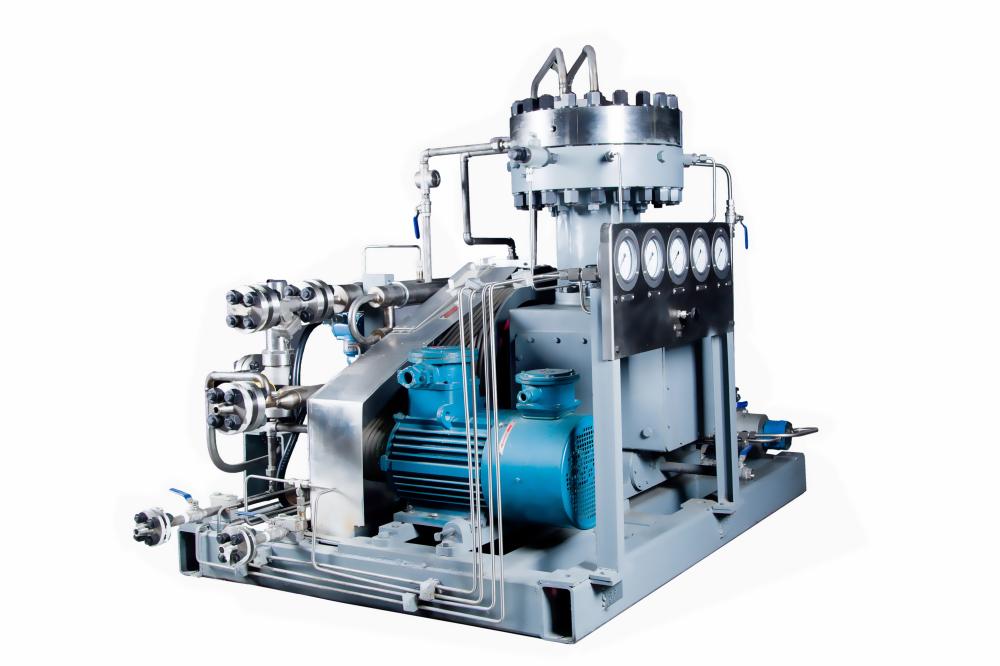

Booster compressor oil and gas are essential for improving effectiveness and performance in various industrial applications. To ensure that equipment farther down operates as efficiently as possible, these devices raise the pressure of gases in a system. Booster compressors must be properly lubricated with high-quality oil and gas to retain their effectiveness and lengthen their lives. This article discusses the value of booster compressor oil and gas in raising productivity and performance, emphasizing how they help to maintain constant operations and minimize downtime.

Lubrication and Heat Dissipation:

Booster compressors work in harsh conditions with frequent high temperatures and pressures. Lubrication and heat dissipation are therefore important. Proper lubrication using specialized compressor oils helps to prevent wear and friction between moving parts, including bearings, pistons, and cylinders. The lubricating oil creates a protective coating on the surfaces by avoiding metal-to-metal contact and reducing the possibility of damage. Additionally, compressor oils help with heat dissipation by removing extra heat produced during compression and keeping the compressor’s operating temperature within reasonable bounds. Effective heat dissipation decreases the risk of system failure and breakdown by preventing overheating.

Energy consumption reduction:

In every industrial activity, efficiency is crucial. Booster compressors function with less energy use when utilizing premium compressor oil and gas. Excellent lubricating qualities in compressor oils provide smooth component movement, reducing energy losses from friction. Reduced friction also causes temperatures to drop, which lowers the energy needed for cooling. Furthermore, high-efficiency compressor oils frequently have lower viscosities, which reduces internal resistance and energy losses during compression.

Increasing Equipment Lifespan:

Booster compressor lifespan may be increased by regular maintenance and appropriate lubrication with the right oils and gases. High-quality compressor lubricants help minimize the danger of early failure by reducing wear and tear on crucial parts, including valves, pistons, and rings. Additionally, lubrication stops the buildup of deposits and rust, which can impair equipment performance and shorten its lifespan. Companies may extend the life of their booster compressors and reduce the frequency of replacements while saving money on maintenance by investing in high-quality lubricants and gases.

Ensure Reliable Operation:

For industrial operations that depend on booster compressors, reliability is a major problem. Unplanned downtime can cause significant financial losses and interfere with business operations. Booster compressors operate more dependably and continuously when the right compressor oil and gas are used. The system’s performance is protected by compounds found in high-quality oils against oxidation, corrosion, and foam formation. Additionally, compressor gases with the proper levels of purity and moisture content helps to maintain stable and effective compressor operation, lowering the possibility of system faults and malfunctions.

Maintenance and monitoring:

To maximize the performance of booster compressor oil and gas, effective maintenance procedures, such as routine oil analysis and monitoring, are crucial. Analyzing the oil makes it possible to evaluate the lubricant’s state and spot any potential problems like contamination or deterioration. This makes it possible to replace the oil or make other necessary corrections on time, avoiding equipment damage and guaranteeing ongoing functioning. Monitoring variables like pressure differentials, temperatures, and vibration levels may also reveal information about how well the compressor system is functioning overall, allowing for preventive maintenance and averting unanticipated breakdowns.

Conclusion:

Any compressor’s effective and dependable operation depends on the presence of booster compressor oil and gas. Oil and gas must be kept in good condition if the compressor functions at its best and provides the necessary output. A compressor may be unable to produce the performance and fuel efficiency it can if the proper oil and gas are not used. We at HUAYAN are working hard to establish ourselves as a leader in this market because we are thoroughly aware of the demands placed on the compressor business. The firm continues to provide dependable and highly effective compressors to industries worldwide with a strong focus on innovation, precise engineering, energy efficiency, and customer satisfaction. Jiangsu Huayan International Trade is a dependable partner committed to offering top-notch products and top-notch service to satisfy various industrial air compression demands.