Oil-free screw air compressor

Oil-free air compressors do not use oil when it comes to compressed air. In other types of compressors, oil is injected to seal rotors, offer lubrication or provide cooling. With oil-free screw compressors, precision is used to create an oil-free option of the highest quality.

Products show

Committed to Manufacturing Solutions

Oil-free water-lubricated screw air compressors are widely used in industries requiring high-quality air sources such as medicine, food, electronics, chemicals, and packaging. Pure compressed air is a necessary measure to ensure process and product quality. You can safely and safely Produce your high-end products efficiently.

The lubrication system of the oil-free screw air compressor is a separate oil supply circulation unit. The compression chamber and the bearing are tightly separated by a high-performance mechanical seal assembly. The lubricating oil can only flow in its closed area and cannot enter the compression area. The compression chamber contains pure air without water, and after a little post-treatment of water and dust removal, pure compressed air can be obtained.

7 advantages of HUAYAN HYW series oil-free and water-lubricated screw compressors:

· 7-inch large touch screen intelligent controller, powerful control and communication functions.

· Adopt the original water-lubricated screw main engine from the Demon Technology Research and Development Center.

· The screw host adopts three-wire meshing and non-equal-width tooth technology, and the meshing pair is in contact with water film, without wear and tear, and the balance of force is good

· The screw host, pipelines and parts are all made of corrosion-resistant special stainless steel materials.

Adopt SKF bearings and independent internal air sealing technology to ensure that the lubricating water does not come into contact with the bearings and maintain the service life of the bearings

· Unique water filtration and lubrication system to ensure good lubrication, sealing, noise reduction and cooling.

· Pure oil-free, oil-free compression system, low noise, super energy-saving.

We can provide to...

- Turn times as short as 24 hours

- 1 to 100,0 units

- Class II Inspection standard and Class III Inspection available

- 100% on-time guarantee

- Ce Certification

-

Program Design

-

Technical Characteristics

-

REOUIREMENTS FOR COMPRESSOR INQUIRY

-

Equipment Exhibition

Our compressors serve many countries in Asia, America, Africa, Europe, Australia, etc.We have a deep understanding of the needs and requirements of the compressor industry, and we are striving to become a leader in this field.

Technical Characteristics

| Power | 7.5-250kw |

| Voltage | 380V 3phase |

| Working Pressure | 7-13bar |

| Flow | 1m³-38m³/min |

| Start Method | Frequency Conversion Start |

| Cooling Method | From HYWV-7G to HYWV-45G Airing cooling HYWV-55G to HYWV-250G Water cooling |

| Material | Stainless Steel |

| Deliver Time | 1 samples Within 3days |

WHEN A CUSTOMER ORDERS A COMPRESSOR OR AN INQUIRY, THE FOLLOWING BASIC PARAMETERS SHOULD BE PROVIDED

| SUCTION PRESSURE MPa(G) | DISCHARGE PRESSURE MPa(G) |

| VOLUME FLOW (NM3/H) |

| SUCTION TEMPERATURE ℃ | DISCHARGE TEMPRETURE ℃ |

| DISCHARGE TEMPRETURE AFTER COOLING ℃ |

Gas Compressor Technology Solutions

- Technical engineers have 30 years of experience in gas compressor design

- The factory area is 91260m2, with more than 50 skilled workers and more than 15 design engineers

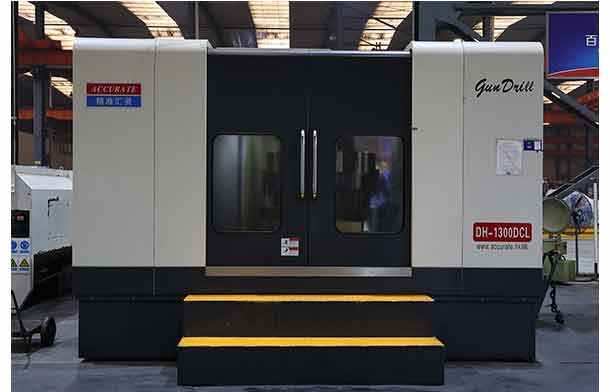

- Own CNC machining center, milling machine, welding, inspection, assembly, testing, storage and other complete production lines.

- Manufacture of inert, flammable, explosive, corrosive and toxic gas compressors

- Professional compressor after-sales service team can provide technical support abroad

- Member of China General Machinery Compressor Industry Association

- Holder of ISO9001, ISO14000, patented technology, EU CE certificate.

- We can better meet the needs of customers and provide cost-competitive products.

Bring you better Products

30 years of compressor design & manufacturing experience

High Frequency asked questions

What is your MOQ?

Are you a factory?

What do I need to do if I want to get proposals and quotes?

Warranty terms of your machine?

Which payment term can you accept?

Can you accept OEM orders?

Why Choose Us?

We have a deep understanding of the needs and requirements of the compressor industry, and we are striving to become a leader in this field.

-

Factory area: 91260m2

-

Technical engineer work experience: 30 years +

-

Exporting countries: 99+

-

Customer Satisfaction: 100%

-

Invention and utility patents: 20+