Quality Inspection

1. Procurement of raw materials: We only purchase quality materials from reputable suppliers to ensure that they meet national quality standards. 2. Production process control: We comprehensively monitor and manage the production process to ensure that every link is in line with standards, so as to avoid defective products. 3. Product testing: We conduct comprehensive testing on each product, including performance, reliability, safety and other indicators, to ensure that the product is fully in line with quality standards. 4. After-sales service guarantee: We provide full after-sales service guarantee, provide professional technical support and after-sales service to all customers, to ensure product quality and performance stability.

98%

99%

-

Supplier Qualification

-

Fine raw material

-

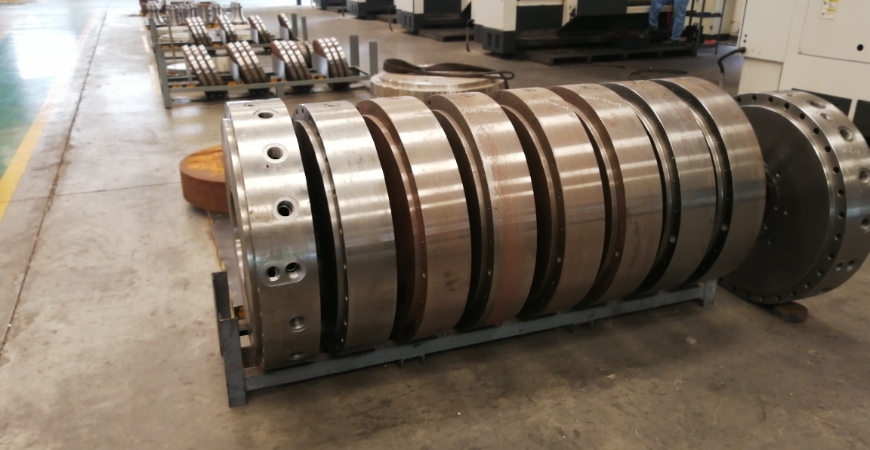

Fine processing of blanks

-

Parts quality

-

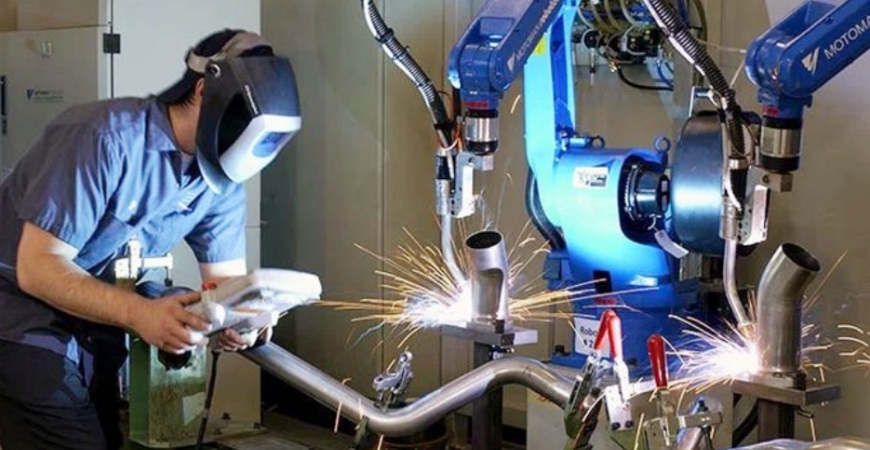

Manual and automatic welding

-

Assembly operation

-

Painting operation

-

Compressor factory test

Supplier Qualification

Select well-known brands at home and abroad, and conduct an annual qualification review on supplier qualification, quality, and reputation.

Over the years, Huayan Gas Equipment has been committed to the field of gas solutions, and has established long-term and stable cooperative relations with well-known domestic and foreign brands. With the improvement of independent research and development capabilities and technical levels, the company can provide product design, engineering development, raw material procurement and Management, manufacturing, testing and other all-round services, the scale of cooperation between the company and suppliers has increased year by year, and the field of cooperation has continued to expand.

Fine raw material

Material composition testing, flaw detection report, quenching and tempering treatment, penetration test, etc. Material identification: 304, 304L, 316 and other stainless steel, 6303, 6062 and other aluminum alloys; metal element content detection: nickel Ni, chromium Cr, molybdenum Mo, iron Fe, etc.

Mechanical properties: tension, bending, yield, fatigue, torsion, stress, stress relaxation, impact, wear, hardness, hydraulic resistance, tensile creep, flaring, flattening, compression, shear strength, etc.;

Process performance: filament drawing, fracture inspection, repeated bending, bidirectional torsion, hydraulic test, flaring, bending, crimping, flattening, ring expansion, ring stretching, micro structure, metallographic analysis;

Failure analysis: fracture analysis, corrosion analysis, etc.; Non-destructive testing: X-ray non-destructive testing, ultrasonic testing, eddy current testing, penetrant testing, magnetic particle testing

Fine processing of blanks

The quality department of the production process monitors and inspects the records throughout the process to prevent defective products from entering the next production process.

Xuzhou Huayan Gas Equipment Co., Ltd. always adheres to strict management, adheres to strict quality control, and strictly controls the manufacturing process of compressors, mainly including the following points:

- Purchasing Control

- Design Control

- Send manufacturing supervision engineers to the manufacturer for on-site supervision

- Quality control of purchased parts

- Traceability of mechanical parts

- Non-destructive testing

Parts quality

Strict inspection of purchased instruments, electrical and other spare parts, zero tolerance for defective and unqualified parts.

Huayan Gas Equipment has strict requirements on suppliers of instrumentation and electrical appliances configured with compressors.

- Recheck the instrumentation of the compressor

- Complete the inspection work according to the inspection process, first inspection, patrol inspection and transfer inspection, and make relevant records

Manual and automatic welding

100% weld inspection is carried out to ensure the pass rate of each welding part.

At present, our company has 15,000 square meters of production plant, with professional and powerful forging.casting, heat treatment,welding, mechanical processing, assembly testing and other production processing capabilities and complete technical testing equipment and means. Advanced processing equipment is an effective measure to ensure the quality of processing, so as to lay a solid foundation for the production of high-quality products.

Assembly operation

A technical engineer with more than 20 years of assembly experience leads the team to control the fit clearance of each component.

Experienced engineers can make accurate predictions based on production process regulations, technical conditions, and production conditions to ensure high-quality production on schedule.

Painting operation

special spraying room for compressors, thermal insulation and environmental protection treatment equipment, to protect the social environment and be responsible for environmental protection.

The company has a professional painting room for painting operation environment, which can meet the requirements of painting operation on temperature, humidity, illuminance, air cleanliness, etc., and can discharge the paint mist and toxic and harmful waste gas generated during painting operation after purification, so as to protect the environment.

Compressor factory test

Strictly control the factory performance of each compressor, simulate the user’s pressure and flow parameters for at least 48 hours of factory test work, and make detailed records.

The company carries out all-staff and whole-process quality control, and strictly inspects the materials purchased; carries out strict self-inspection, mutual inspection and special inspection control on cutting, turning milling. planer, drilling, grinding, boring, marking, welding, assembly and other production processes; and carries out continuous operation of the completed machine for no less than 48 hours. Conditions simulation test to ensure that all performance parameters meet all kinds of standards