Integrated Air Compressor

The integrated air compressor can be used to both inflate and deflate to pre-set defined pressures. Designed for adjusting tyre pressures as well as to inflate bicycle tyres with Schrader valves, air beds and other inflatable items such as the inflatable waterproof awning.

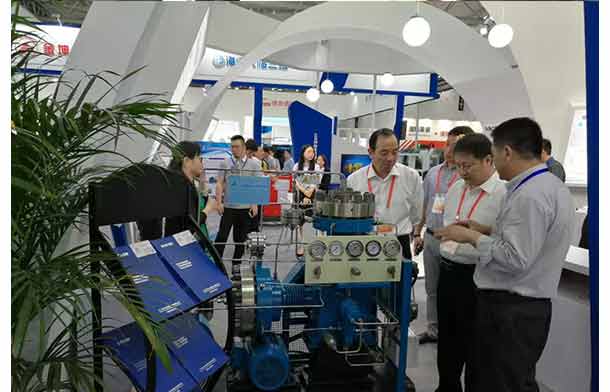

PCB Products show

Committed to Manufacturing Solutions

The integrated air compressor has the following features

1. The integrated air compressor includes a screw compressor, a refrigeration dryer, a precision filter, an air storage tank and other components.

2. After the air passes through the integrated system, the air quality is obviously optimized, which can meet the process needs of various enterprises.

3. Space-saving, compact compressed air system.

4. Complete system, no additional drying system, no installation cost for connecting pipelines.

5. Easy to use, flexible and lightweight, users can use high-quality compressed air after connecting the power supply.

6. The integrated electric control box simultaneously controls the compression system and the drying system, which greatly improves the efficiency of use. It is different from similar products without centralized control, which is not a real integrated screw compressor.

7. It can be installed modularly in the supporting production line to improve the integrity of the production system

8. Beautiful appearance, reliable performance, superior economy

We can provide to...

- Turn times as short as 24 hours

- 1 to 100,0 units

- Class II Inspection standard and Class III Inspection available

- 100% on-time guarantee

- Ce Certification

-

Program Design

-

Technical Characteristics

-

REOUIREMENTS FOR COMPRESSOR INQUIRY

-

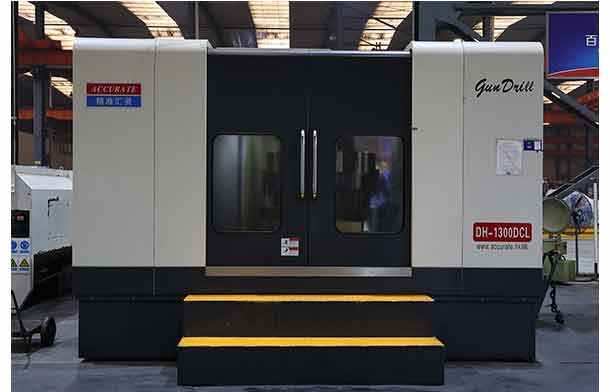

Equipment Exhibition

Our compressors serve many countries in Asia, America, Africa, Europe, Australia, etc.We have a deep understanding of the needs and requirements of the compressor industry, and we are striving to become a leader in this field.

Technical Characteristics

| Power | 5.5~37 KW |

| Voltage | 380V 3phase |

| Working Pressure | 7-13bar |

| Flow | 0.52~6.50 M³/min |

| Fuel Tank Capacity | 65-400L |

| Cooling Method | Airing cooling / Water cooling |

| Material | Stainless Steel |

| Deliver Time | 1 samples Within 3days |

WHEN A CUSTOMER ORDERS A COMPRESSOR OR AN INQUIRY, THE FOLLOWING BASIC PARAMETERS SHOULD BE PROVIDED

| SUCTION PRESSURE MPa(G) | DISCHARGE PRESSURE MPa(G) |

| VOLUME FLOW (NM3/H) |

| SUCTION TEMPERATURE ℃ | DISCHARGE TEMPRETURE ℃ |

| DISCHARGE TEMPRETURE AFTER COOLING ℃ |

Gas Compressor Technology Solutions

- Technical engineers have 30 years of experience in gas compressor design

- The factory area is 91260m2, with more than 50 skilled workers and more than 15 design engineers

- Own CNC machining center, milling machine, welding, inspection, assembly, testing, storage and other complete production lines.

- Manufacture of inert, flammable, explosive, corrosive and toxic gas compressors

- Professional compressor after-sales service team can provide technical support abroad

- Member of China General Machinery Compressor Industry Association

- Holder of ISO9001, ISO14000, patented technology, EU CE certificate.

- We can better meet the needs of customers and provide cost-competitive products.

Bring you better products

30 years of compressor design & manufacturing experience

High Frequency asked questions

What is your MOQ?

Are you a factory?

What do I need to do if I want to get proposals and quotes?

Warranty terms of your machine?

Which payment term can you accept?

Can you accept OEM orders?

Why Choose Us?

We have a deep understanding of the needs and requirements of the compressor industry, and we are striving to become a leader in this field.

-

Factory area: 91260m2

-

Technical engineer work experience: 30 years +

-

Exporting countries: 99+

-

Customer Satisfaction: 100%

-

Invention and utility patents: 20+